True Welding Artisans

Since 1987, Five Star Tool Welding has serviced hundreds of manufacturers who have benefited from our strict attention to detail.

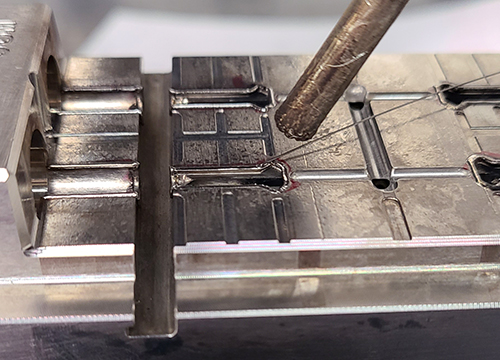

Our experienced Laser and Micro Welding technicians are perfectionists, true artisans providing the strongest, highest quality results. You can be assured that your tool will last, and, in some cases, perform better than before.

At Five Star Tool Welding, we have the most advanced equipment in the industry and are ready to work for you.

Whether you’re making injection molds for the medical industry or trying to regain the fine definition in your intricate die, we have the best tool for the situation. We are proud of the craftsmanship we provide and carefully inspect each weld to make sure it has been done correctly and looks incredible.

Our welders have extensive experience in welding a wide range of materials including:

H-13, S-7, P-20, Aluminum including 7000 series and QC7, Moldstar 90, Moldmax HH, A-2, A-6, D-2, M-2, T-1, Powdered (sintered) Metals, CPM, DC 53, Stainless Steel 300 and 400 Series, Caldie, Dievar, Tuf-Die, Aluminum Bronze Alloys (Ampco 940 and Ampco 945)

Our team is as fast as it is skilled.

The typical turnaround time for a project is two to three days.

This means less down time for you. We use the fastest shipping methods to make sure you get your finished product as soon as possible.